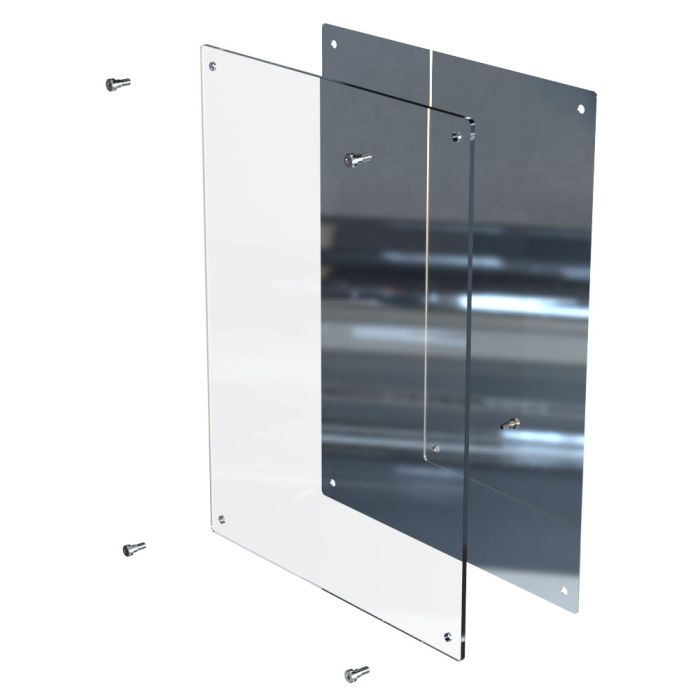

Shatterproof Stainless Steel Safety Mirror with Protective Layer

The AA-PSM-PL Shatterproof Stainless Steel Safety Mirror features a highly polished #8 stainless surface protected by a sacrificial polycarbonate layer for superior safety and long-term performance. Ideal for public restrooms, schools, and high-abuse environments, this mirror eliminates the risk of broken glass and allows quick replacement of scratched or damaged protective covers. Made in the USA with surface-mount installation and available in multiple standard and custom sizes.

Mounting Hardware: is not provided due to the variety of materials our customers mount to. We recommend the following to make replacement of plexi-glass easy while still maintaining security:

Note 1: Custom Shapes & Sizes Available Upon Request, Call for Details

Note 2: Custom size option on website is for reference only. $0 is NOT the actual purchase price - a quote must be generated.

Note 3: See "Mirror Surface" in detailed description below to understand the difference between this and a glass based mirror.

ADA Compliant (AA-PSM-PL)

Warranty Guide, Care Instructions & Spec Sheet - See Spec Sheet Tab Below

AA-PSM-PL Shatterproof Stainless Steel Safety Mirror with Anti-Graffiti Polycarbonate Protection

Product Overview

The AA-PSM-PL is a vandal-resistant, glass-free safety mirror constructed from highly polished #8 stainless steel with a sacrificial polycarbonate overlay for added protection. Designed for high-traffic, high-impact environments such as correctional facilities, schools, transportation hubs, and industrial restrooms, this mirror eliminates glass breakage risks while providing a functional, clear reflection. The polycarbonate layer can be removed, cleaned, or replaced if scratched or vandalized, making it a long-term, cost-effective solution.

Key Features

- Polished Stainless Steel Mirror Surface: #8 mirror finish offers near-glass reflective quality without the fragility of traditional mirrors.

- Shatterproof Design: No risk of dangerous glass shards, ideal for safety-critical environments.

- Anti-Graffiti Protection: Polycarbonate sacrificial layer protects against scratches, graffiti, and impact damage.

- Made in the USA: Engineered for long-term durability in public and institutional settings.

- Corrosion Resistant: Stainless steel construction resists rust, chemicals, and cleaning agents.

- Available Sizes: 18”x24”, 18”x36”, 24”x36”, 24”x60”, 48”x60” (Custom sizes available upon request).

- Surface-Mounted Installation: 3/8” mounting holes for secure wall mounting using tamper-resistant hardware.

- LEED-Friendly Construction: Built with sustainable, environmentally conscious materials.

Specifications

- Depth: 5/16"

- Material: 18-gauge 304L Stainless Steel with #8 mirror finish and polycarbonate overlay

- Mounting: 3/8” Surface Mounting Hole Placements (hardware not included)

- Model Options: AA-PSM-PL-18x24-#8M-18g, AA-PSM-PL-18x36-#8M-18g, AA-PSM-PL-24x36-#8M-18g, AA-PSM-PL-24x60-#8M-18g, AA-PSM-PL-48x60-#8M-18g

Graffiti / Scratch Removal from Sacrificial Layer

This mirror features two main components: a polished stainless steel base and a protective polycarbonate overlay. Minor scratches in the steel can be polished out using a mild abrasive and buffing wheel. Scratches in the polycarbonate can be repaired using a heat gun. In cases of deep damage, the polycarbonate layer is fully replaceable, preserving the mirror's clean, clear appearance over time. A video tutorial is available for guidance.

Installation Recommendations

For secure and serviceable installation, use hanger bolts with tamper-proof security nuts. Ensure 3/4” or greater back bracing. Use 3/8” stainless steel fasteners appropriate for the surface. Through-bolting is highly recommended for partition walls and high-impact applications.

Installation Note

The mirror’s reflective side is covered with a grey protective film printed with blue text. This film must be peeled off before use. The back side, although slightly reflective, will not be covered. Due to the precision of laser cutting, the film may be difficult to remove—but it is intended to come off before installation.

Inspection Prior to Installation

Upon delivery, inspect and photograph the unopened mirror from all sides to document any shipping damage. Carefully lay the mirror flat, remove the protective film, and check for any dents, warping, or damage. Minor visual imperfections may be present due to the nature of the material. Any defects must be reported prior to installation. Once installed, the product is considered accepted by the contractor or end user.

Mirror Surface and Reflection Quality

Though similar in appearance to glass, stainless steel mirrors may exhibit minor surface distortion. A “double image” effect may also occur due to light reflecting off both the polycarbonate and stainless steel layers. This is normal and inherent to the layered design. These mirrors prioritize durability and safety over perfect optical clarity, making them ideal for challenging environments where standard mirrors fail.

High Moisture Environments

If installed in wet or humid areas, seal the edges between the polycarbonate and stainless steel to prevent moisture buildup and potential mold growth.

Cleaning and Maintenance Instructions

- Use a Mild Cleaner: Apply non-abrasive cleaner (like Windex) and wipe with a microfiber cloth.

- Dry Thoroughly: Always ensure the surface is completely dry to prevent moisture accumulation.

Following these guidelines ensures long-lasting durability and maintains the mirror’s appearance over time.

Competitor Comparison

Unlike traditional glass mirrors or basic metal panels, the AA-PSM-PL offers a dual-layer system with replaceable protection and no risk of shattering. Brands such as Bobrick B-165 cannot match the combination of safety, durability, and serviceability this mirror provides in demanding public or institutional settings.

Made to Order Items

All of Vandal Stop Products are made by hand in the USA using American-sourced stainless steel. While some products might be available in stock, most are made to order. Our general estimated lead times are:

- Quantity 1 - 10 = ~4 to 6 weeks for production

- Quantity 11 - 50 = ~4 to 8 weeks for production

- Quantity 51 - 100 = ~6 to 10 weeks for production

- Quantity 101 - 200 = ~10 to 16 weeks for production

- Quantity 200+ = Call for estimate

Winter Months Production

Due to holidays and winter weather, some production delays may occur during the months of November, December, January, and February.

Supply Chain

Due to increased demand, more time be required for production. If you have a critical delivery date requirement, please call or email to verify lead times prior to placing an order.

Stocked Items

For certain items that we sell often, we do our best to either keep inventory on the shelf or keep a constant production cue going. For items that are considered "stocked" we will generally be able to ship within 5 business days or less.

Why Are Stocked Items More Expensive?

We're adapting to your needs! While we specialize in made-to-order products, we recognize the growing demand for immediate availability. Adjusting to this requires foresight in demand anticipation, material procurement, initiating stock production, and warehousing—all incurring additional costs. Consequently, our stocked items are priced to reflect these overheads. For customers who can accommodate a production lead time, we're pleased to offer discounted pricing as a thank you for your flexibility.

Billing

Credit Card orders will be charged at the time of checkout. If you wish to be billed when your order ships, you can use the "Pay by Purchase Order" option on the payment section of checkout. You will be asked to upload a PDF copy of your Purchase Order along with a reseller certificate of tax exempt status is applicable. We will invoice you once your order has been shipped.

For more information, contact us or read our full Production Lead Times Policy.